Automation Commissioning

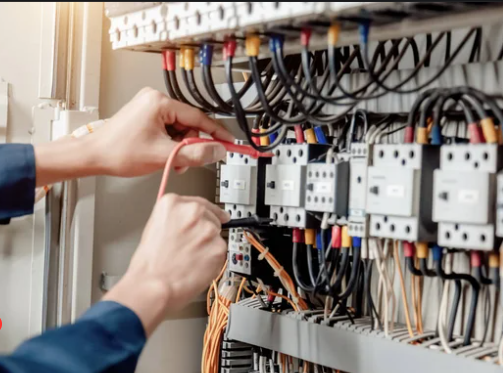

At WK Automation & Electrical we get your systems up and running faster with our automated commissioning services. Our experts simplify the process and save you time & money by ensuring your systems are installed according to the required design and meets your operational needs.

Our Services:

- Preparation and Planning: This phase involves defining the scope and objectives of the automation commissioning process. It includes reviewing design documents, specifications, and functional requirements to create a detailed commissioning plan.

- Installation and Integration: The automation system or equipment is physically installed and integrated into the existing infrastructure. This may include setting up hardware components, connecting sensors and actuators, and configuring communication interfaces.

- Software Configuration: If the automation system involves software components, such as a control system or PLC (Programmable Logic Controller), the necessary software is configured and programmed to perform the desired functions.

- Functional Testing: Each component of the automation system is tested individually to verify that it performs its intended function correctly. This step ensures that individual hardware and software elements are functioning as expected.

- Integrated System Testing: After verifying the individual components, the entire automation system is tested as a whole to ensure that all components work together harmoniously and that data flows smoothly between them.

- Performance Testing: Performance testing involves assessing the automation system's performance under different conditions and stress levels to ensure it meets required performance criteria.

- Safety Testing: For automation systems involving critical processes or equipment, safety testing is essential to validate that safety protocols and interlocks function correctly and prevent any hazardous situations.

- Operator Training: The commissioning process includes training the operators and maintenance personnel to ensure they understand the system's operation, troubleshooting, and maintenance procedures.

- Documentation and Handover: Throughout the commissioning process, comprehensive documentation is created, including test results, configurations, and user manuals. Once commissioning is complete, the automation system is handed over to the operations team.

- Validation and Acceptance: The client or end-user validates the automation system's performance against the specified requirements. After successful validation, formal acceptance is granted, and the system is officially put into operation.

- Post-Commissioning Support: Following commissioning, the automation provider typically offers post-commissioning support to address any issues that may arise during initial operation and ensure the system's long-term stability.